Product

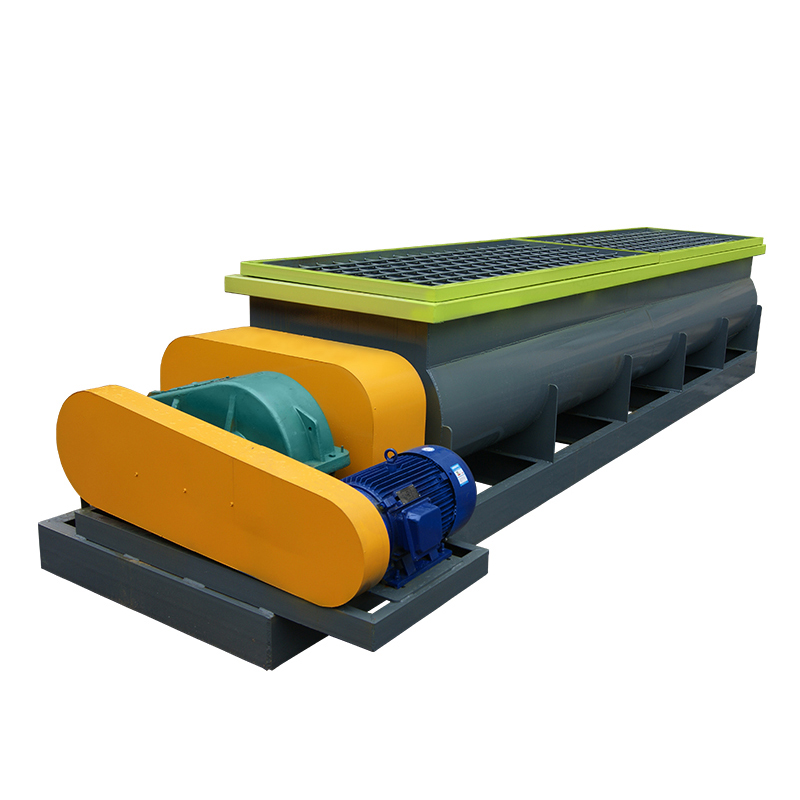

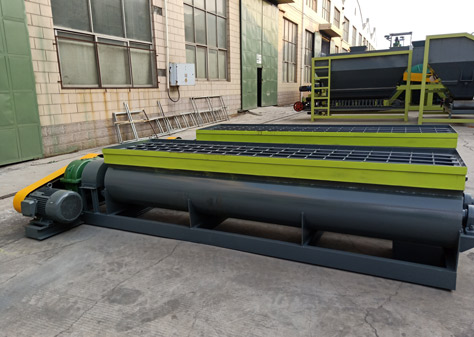

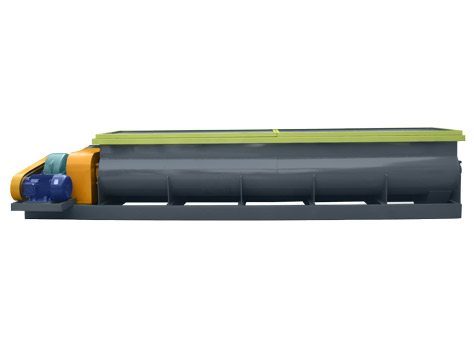

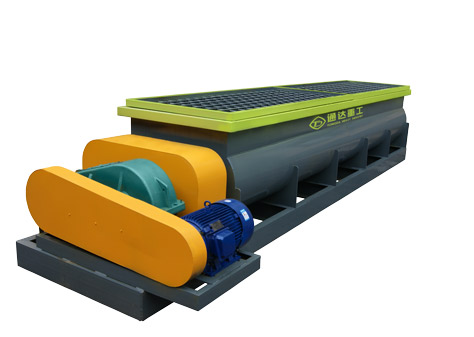

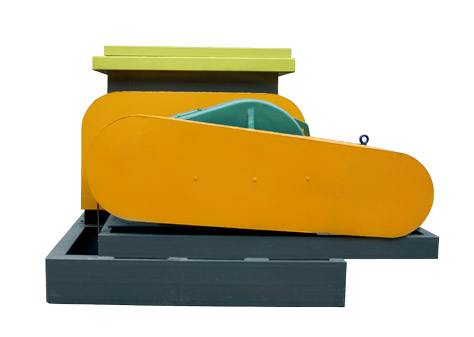

Double Shafts Horizontal Mixer

PRODUCT DETAILS

Double shafts horizontal mixer is suitable for continuous mixing of mixed fertilizer powder,usually used after automatic batching equipment.The working principle is that the materials go into the mixing tank,then through a pair of screw shafts with opposite rotating,they are stirred uniform,and enter the next granulation process.

|

Model |

Power (kw) |

Outer Diameter of Mixing Shaft (mm) |

Reducer type |

Mixing Speed (r/min) |

Dimensions (mm) |

|

TDSJ-8030 |

11 |

420 |

ZQ350-31.5 |

35 |

3700*800*750 |

|

TDSJ-1050 |

22 |

650 |

ZQ500-31.5 |

35 |

6200*1300*1200 |

- High efficiency and high wear resistant alloy. It has high mixing efficiency and small floor space. The spiral blade is made of a highly wear-resistant special alloy.

- The two-shaft wet mixer is driven by a reducer, which has stable rotation and low noise.

- The twin-shaft mixer is fed from the top and discharged at the bottom, and the structure is reasonable.

- The seal between the joint surfaces is tight and the operation is stable.

When the dry powdery material is fed into the tank by the feeding nozzle, then the power transmission mechanism drives the spiral spindle rotation of the multi-group blades. By driving the passive helical shaft and the main shaft of the meshing transmission gear, the material is stirred and pushed to the tank and the wet section. After the material is pushed into the humidification section, the humidifier automatically sprays the material, and then the mixing section is fully stirred. When the material reaches the controllable humidity, it is removed from the outlet and enters the next process.