Product

Organic Fertilizer Manufacturing Production Line

PRODUCT DETAILS

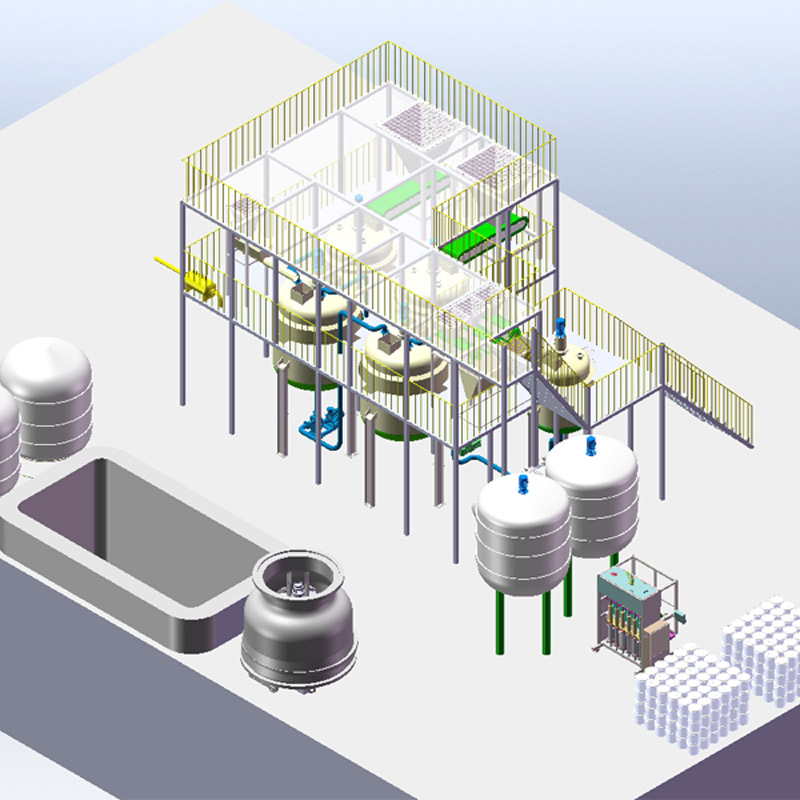

The organic fertilizer production plant is commonly used to process different fermented organic substance into organic fertilizer.It adopts one-step molding technology. Animal manure and agricultural waste are recycled as the main raw materials, the development of organic fertilizer production line and sterilization system using livestock and poultry manure. It will effectively promote the development of ecological agriculture and circular economy.

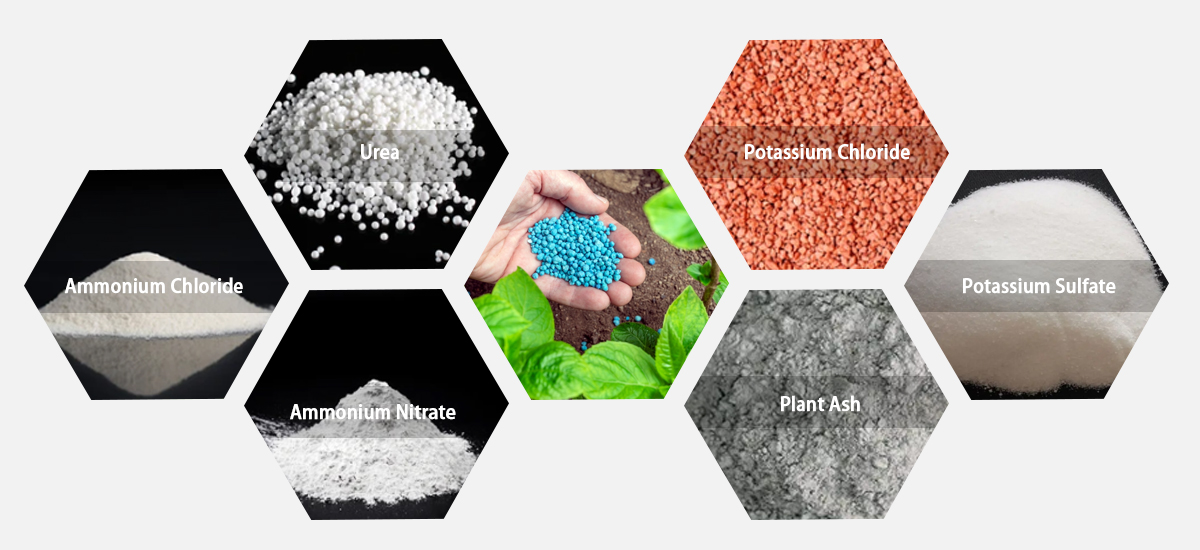

Raw material of organic fertilizer manufacturing production plant:

1. Agricultural waste: Straw, dregs of beans, cotton dregs, rice bran, etc.

2. Animal manure: Mixture of poultry litter and animal waste, such as the wastes of slaughterhouse, fish market, urine and dung of cattle,

Pigs, sheep, chicken, ducks, geese, goat, etc.

3. Industrial waste: Wine lees, vinegar residue, manioc waste, sugar scum, furfural residue, etc.

4. Home scrap: Food waste, the roots and leaves of vegetables, etc.

5. Sludge: The sludge of the river, sewer, etc.

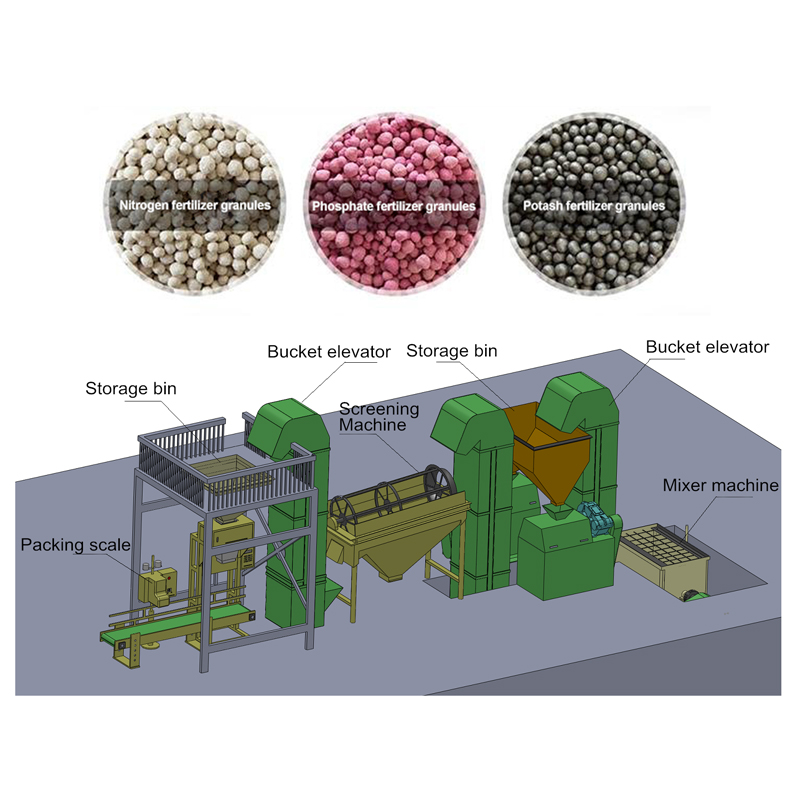

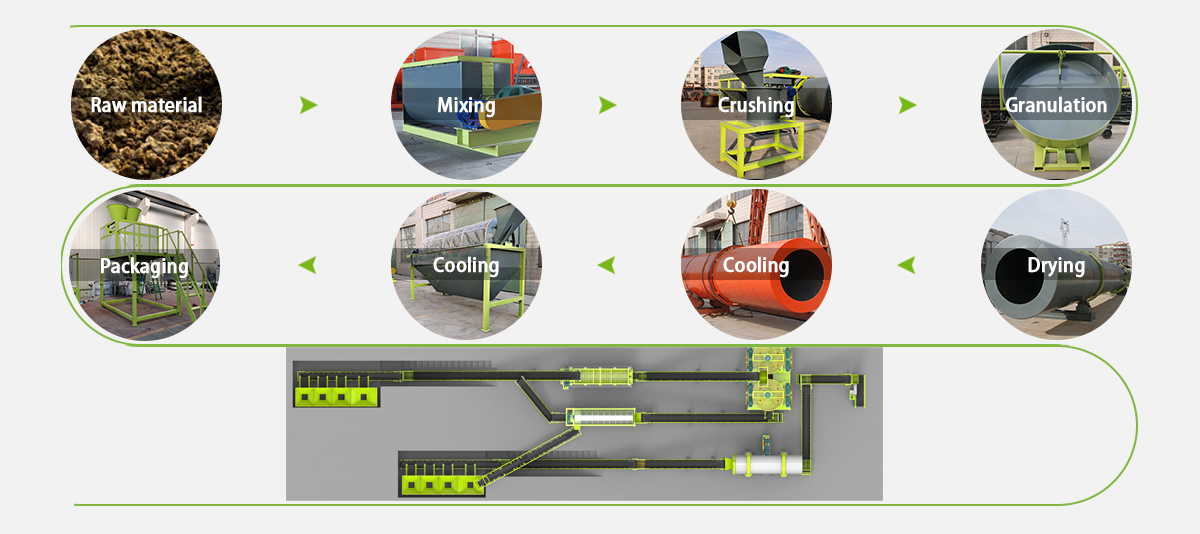

The whole organic fertilizer production line include the following machines:raw material fermentation→ fertilizer crushing machine→ fertilizer mixing machine → fertilizer rotary drum granulator → fertilizer rotary drum drying/cooling machine → fertilizer rotary drum coating machine → fertilizer rotary screening machine → fertilizer packaging machine → belt conveyor → and other accessories.

1.Organic materials fermentation process plays the preliminary but indispensable role in the whole fertilizer production line. Two main types of compost turner are widely used to turn and mix the compost and accelerate the fermentation speed: Self-propelled compost turner and hydraulic compost turner.

2.Crushing process: The compost lump materials should be ground before the granulating process. But we can leave out crushing process when the compost material is fine enough. Vertical chain crusher and double-shaft horizontal crusher, two types of crushing machine can be used to crush lump compost fertilizer raw materials.

3.Mixing process, two types of mixing machine are applied to mix raw materials in the fertilizer production line: Horizontal mixer and vertical mixer.

4.Drying process. When fertilizer granulating, the moisture of fertilizer raw materials should be less than 25%, so we should dry the raw materials if the moisture is more than 25%. Rotary drum drying machine is mainly used for drying the fertilizer with a certain degree of humidity and particle size.

5.Fertilizer granulator process. Granulating process is the core part in this production line, so we choose the suitable model of fertilizer granulator according to customers detailed requirements.Optional granulator equipment: Organic fertilizer combination granulator, organic fertilizer special granulator, pair roll extrusion granulator, disc granulator, flat film granulator, bio organic fertilizer spherical granulator, drum granulator, round tossing machine, etc.; typical application materials: Chicken manure, cow dung, kaolin, etc.

6.Rotary drum cooling machine is used for cooling fertilizer to make fertilizer particles stronger.

7.Screening process:Rotary drum screening machine is used to separate the granules from the large particles which need to be returned for the second crushing and granulating. Rotary drum coating machine is used to coat the fertilizer and prevent the fertilizer from sticking together.

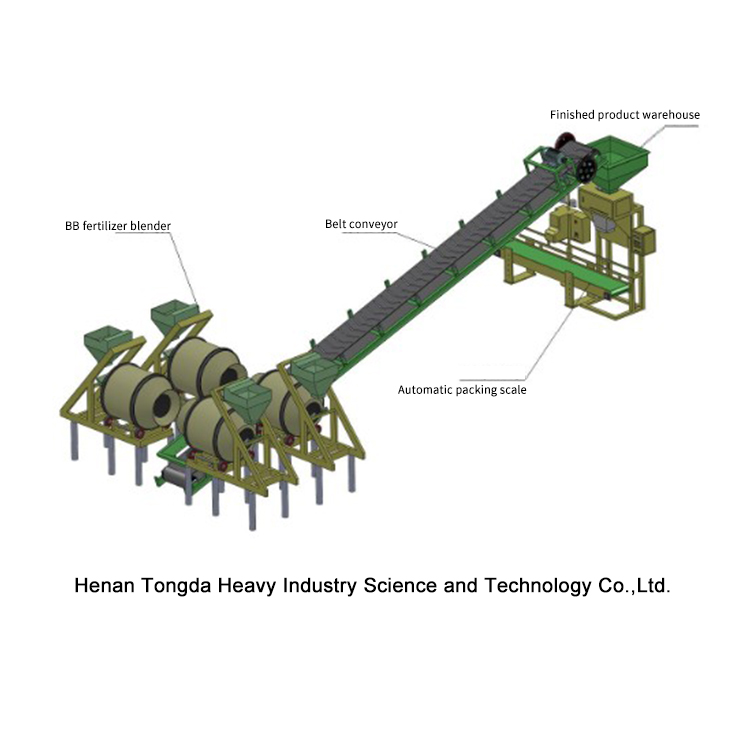

8.The last process is packaging process. Fertilizer packaging machine can package bags quantitatively and automatically.Including electronic quantitative packaging scale.It also need some auxiliary equipment for connection such as belt conveyor, bucket elevator, etc.

High production efficiency:

All the process are automatic operation.Simple operation, only two people can operate.

Low operating cost and low energy consumption:

All kinds of animal manure can be processed. 4 hours biological deodorization. Waste heat recovery energy saving and environmental protection. Suitable for large, medium and small farms.

Wide used of the finished products:

Pig farm breeding, cattle farm,etc.. The application of this type manure compost fertilizer making machine has a very positive significance for environmental protection.