Product

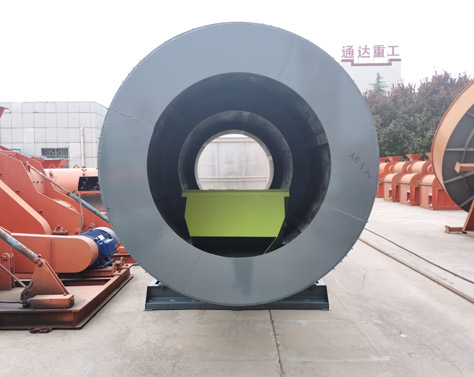

Rotary Drum Fertilizer Granulator

PRODUCT DETAILS

Rotary drum fertilizer granulator is a molding machine that can make material into a particular shape. The rotary drum granulator is one of the key equipment of the organic and compound fertilizer industry.It is suitable for cold or hot granulation and mass production for high and low concentration compound fertilizer. The main operation way is wet type granulation: Through a certain amount of water or steam, the basic fertilizer humidifying in the tank and occurring sufficient chemical reaction. Under a certain liquid conditions, with the rotation of the rotary drum movement, so that produce a squeeze force between the material particles and agglomerate into balls.

|

Model |

Power(kw) |

Diameter(mm) |

Length(mm) |

Installation Angle(degree) |

Rotary Speed(r/min) |

Capacity(t/h) |

|

TDZGZ-1240 |

5.5 |

1200 |

4000 |

2-5 |

17 |

1-3 |

|

TDZGZ-1560 |

11 |

1500 |

6000 |

2-5 |

11.5 |

3-5 |

|

TDZGZ-1870 |

15 |

1800 |

7000 |

2-5 |

11.5 |

5-8 |

|

TDZGZ-2080 |

18.5 |

2000 |

8000 |

2-5 |

11 |

8-15 |

|

TDZGZ-3210 |

37 |

3200 |

10000 |

2-5 |

9.5 |

15-30 |

- Technical innovation and structural improvement, the tube adopts special rubber plate lining or acid-resistant stainless steel lining, which realizes automatic scar removal and tumor removal and eliminates the traditional scraper device.

- High wear resistance, easy maintenance, high ball strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life, easy operation and maintenance.

- Reasonable layout, leading technology, small power, no waste discharge, stable operation, convenient maintenance, reasonable process layout, advanced technology, low production cost.

- High pelletizing rate, high drying efficiency, pelletizing rate up to 70%, with a small amount of return material, return material particle size is small, can be re-granulated;Through steam heating, improve the material temperature

The main working principle is wet type granulation: Through a certain amount of water or steam, the basic fertilizer humidifying in the tank and occurring sufficient chemical reaction. Under a certain liquid conditions, with the rotation of the rotary drum movement, so that produce a squeeze force between the material particles and agglomerate into balls.