Product

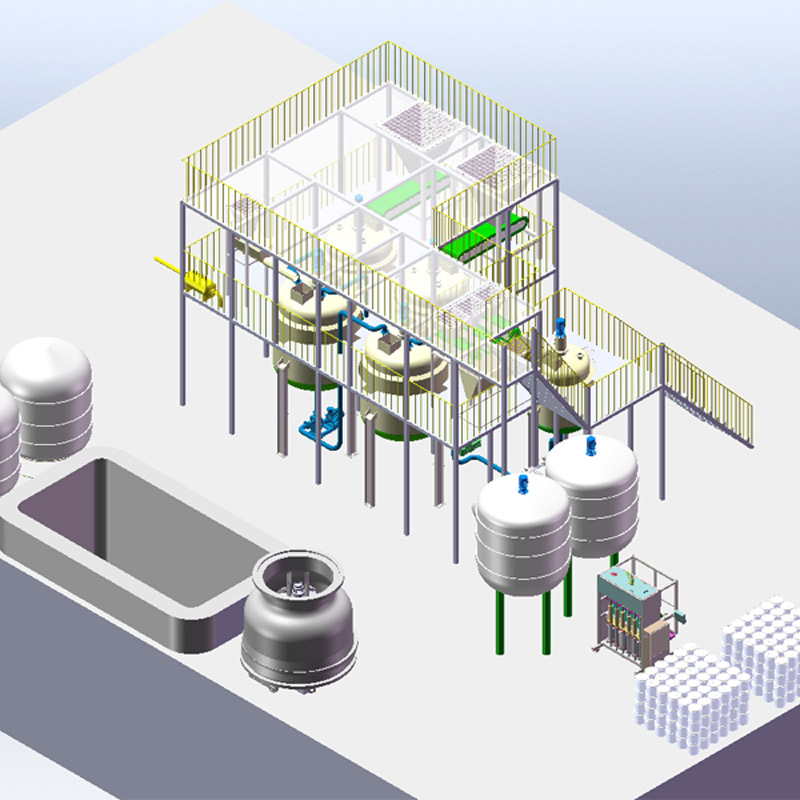

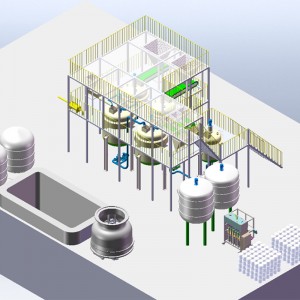

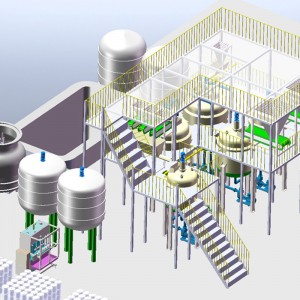

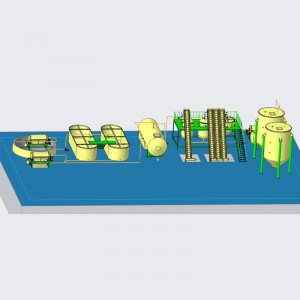

Water Soluble Fertilizer Production Line

PRODUCT DETAILS

Introduction of fermentation process:

Biogas fermentation, also known as anaerobic digestion and anaerobic fermentation, refers to organic matter (such as human, livestock and poultry manure, straw, weeds, etc.) under certain moisture, temperature and anaerobic conditions, through the catabolism of various microorganisms, and finally The process of forming a flammable mixture of gases such as methane and carbon dioxide. The biogas fermentation system is based on the principle of biogas fermentation, with the goal of energy production, and finally realizes the comprehensive utilization of biogas, biogas slurry and biogas residue.

Biogas fermentation is a complex biochemical process with the following characteristics:

(1) There are many types of microorganisms involved in the fermentation reaction, and there is no precedent for using a single strain to produce biogas, and inoculum is needed for fermentation during production and testing.

(2) The raw materials used for fermentation are complex and come from a wide range of sources. Various single organic matter or mixtures can be used as fermentation raw materials, and the final product is biogas. In addition, biogas fermentation can treat organic wastewater with a COD mass concentration exceeding 50,000 mg/L and organic waste with a high solid content.

The energy consumption of biogas microorganisms is low. Under the same conditions, the energy required for anaerobic digestion only accounts for 1/30~1/20 of aerobic decomposition.

There are many types of biogas fermentation devices, which are different in structure and material, but all kinds of devices can produce biogas as long as the design is reasonable.

Biogas fermentation refers to the process in which various solid organic wastes are fermented by biogas microorganisms to produce biogas. It can generally be divided into three stages:

Liquefaction stage

Since various solid organic matter usually cannot enter the microorganisms and be utilized by microorganisms, the solid organic matter must be hydrolyzed into Soluble monosaccharides, amino acids, glycerol, and fatty acids with relatively small molecular weights. These soluble substances with relatively small molecular weight can enter the microbial cells and be further decomposed and utilized.

Acidogenic stage

Various soluble substances (monosaccharides, amino acids, fatty acids) continue to decompose and transform into low molecular substances under the action of cellulosic bacteria, protein bacteria, lipobacteria, and pectin bacteria intracellular enzymes, such as butyric acid, propionic acid, acetic acid, and alcohols , ketones, aldehydes and other simple organic substances; at the same time, some inorganic substances such as hydrogen, carbon dioxide and ammonia are released. But in this stage, the main product is acetic acid, accounting for more than 70%, so it is called the acid generation stage. Bacteria that participate in this phase are called acidogens.

Methanogenic stage

Methanogenic bacteria decompose simple organic matter such as acetic acid decomposed in the second stage into methane and carbon dioxide, and carbon dioxide is reduced to methane under the action of hydrogen. This stage is called the gas production stage, or the methanogenic stage.

Methanogenic bacteria require to live in an environment with an oxidation-reduction potential below -330mV, and biogas fermentation requires a strict anaerobic environment.

It is generally believed that from the decomposition of various complex organic matter to the final generation of biogas, there are five major physiological groups of bacteria involved, which are fermentative bacteria, hydrogen-producing acetogenic bacteria, hydrogen-consuming acetogenic bacteria, hydrogen-eating methanogens and acetic acid-producing bacteria. Methanogens. Five groups of bacteria constitute a food chain. According to the difference of their metabolites, the first three groups of bacteria complete the process of hydrolysis and acidification together, and the latter two groups of bacteria complete the process of methane production.

fermentative bacteria

There are many kinds of organic matter that can be used for biogas fermentation, such as livestock manure, crop straw, food and alcohol processing waste, etc., and its main chemical components include polysaccharides (such as cellulose, hemicellulose, starch, pectin, etc.), lipids class and protein. Most of these complex organic substances are insoluble in water and must first be decomposed into soluble sugars, amino acids and fatty acids by extracellular enzymes secreted by fermentative bacteria before they can be absorbed and utilized by microorganisms. After the fermentative bacteria absorb the above-mentioned soluble substances into the cells, they are converted into acetic acid, propionic acid, butyric acid and alcohols through fermentation, and a certain amount of hydrogen and carbon dioxide are produced at the same time. The total amount of acetic acid, propionic acid and butyric acid in the fermentation broth during biogas fermentation is called total volatile acid (TVA). Under the condition of normal fermentation, acetic acid is the main acid in the total exerted acid. When protein substances are decomposed, in addition to the products, there will also be ammonia hydrogen sulfide. There are many types of fermentative bacteria involved in the hydrolytic fermentation process, and there are hundreds of known species, including Clostridium, Bacteroides, Butyric acid bacteria, Lactic acid bacteria, Bifidobacteria and Spiral bacteria. Most of these bacteria are anaerobes, but also facultative anaerobes. [1]

Methanogens

During biogas fermentation, methane formation is caused by a group of highly specialized bacteria called methanogens. Methanogens include hydromethanotrophs and acetomethanotrophs, which are the last group members in the food chain during anaerobic digestion. Although they have a variety of forms, their status in the food chain makes them have a common physiological characteristics. Under anaerobic conditions, they convert the final products of the first three groups of bacterial metabolism into gas products methane and carbon dioxide in the absence of external hydrogen acceptors, so that the decomposition of organic matter under anaerobic conditions can be successfully completed.

Plant nutrient solution process selection:

The production of plant nutrient solution intends to use the beneficial components in the biogas slurry and add enough mineral elements to make the finished product have better characteristics.

As a natural macromolecular organic matter, humic acid has good physiological activity and functions of absorption, complexation and exchange.

The use of humic acid and biogas slurry for chelation treatment can increase the stability of biogas slurry, adding trace element chelation can make crops better absorb trace elements.

Humic acid chelation process introduction:

Chelation refers to a chemical reaction in which metal ions are linked with two or more coordination atoms (non-metal) in the same molecule by coordination bonds to form a heterocyclic structure (chelate ring) containing metal ions. kind of effect. It is similar to the chelation effect of crab claws, hence the name. The formation of the chelate ring makes the chelate more stable than the non-chelate complex with similar composition and structure. This effect of increasing stability caused by chelation is called the chelation effect.

A chemical reaction in which a functional group of one molecule or two molecules and a metal ion forms a ring structure through coordination is called chelation, also known as chelation or cyclization. Among the inorganic iron ingested by the human body, only 2-10% is actually absorbed. When minerals are converted into digestible forms, amino acids are usually added to make it a “chelate” compound . First of all, Chelation means to process mineral substances into digestible forms. Ordinary mineral products, such as bone meal, dolomite, etc., have almost never been “chelated”. Therefore, in the digestion process, it must first undergo “chelation” treatment. However, the natural process of forming minerals into “chelate” compounds (chelate) compounds in most people’s bodies does not work smoothly. As a result, mineral supplements are almost useless. From this we know that the substances ingested by the human body cannot fully exert their effects. Most of the human body cannot effectively digest and absorb food. Among the inorganic iron involved, only 2%-10% is actually digested, and 50% will be excreted, so the human body has already “chelated” iron. “The digestion and absorption of treated minerals is 3-10 times higher than that of untreated minerals. Even if you spend a little more money, it’s worth it.

The currently commonly used medium and trace element fertilizers usually cannot be absorbed and utilized by crops because inorganic trace elements are easily fixed by the soil in the soil. Generally, the utilization efficiency of chelated trace elements in soil is higher than that of inorganic trace elements. The price of chelated trace elements is also higher than that of inorganic trace element fertilizers.