Product

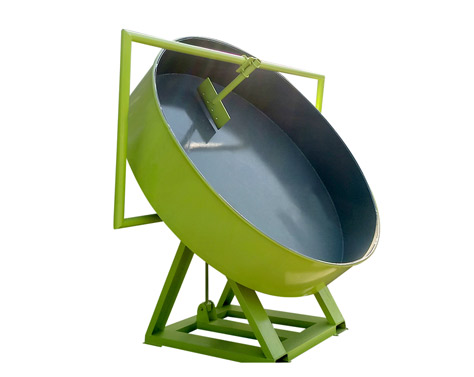

Manure Organic Fertilizer Disc Pelletizer

PRODUCT DETAILS

Disc granulator (also known as the ball plate) adopts the whole circular arc structure, and the granulating rate can reach more than 93%. It has three discharging ports, which is convenient for discontinuous production, greatly reducing the labor intensity and improving the labor efficiency. The reducer and motor use flexible belt drive to start smoothly, slow down the impact force and improve the service life of the equipment. The plate bottom is strengthened by a plurality of radiant steel plates, which is durable and never deformed. It is an ideal equipment for organic fertilizer and compound fertilizer, which is designed with thick, heavy and strong base, so it has no fixed anchor bolts and smooth operation.

|

Model |

Diameter of Disc(mm) |

Edge Height (mm) |

Rotary Speed (r/min) |

Motor Power (kw) |

Capacity (t/h) |

Model of Reducer(kw) |

Dimensions(mm) |

|

TDYZ-500 |

500 |

200 |

32 |

0.55 |

0.02-0.05 |

BWYO-43-0.55 |

650*600*800 |

|

TDYZ-600 |

600 |

280 |

33.5 |

0.75 |

0.05-0.1 |

BWYO-43-0.55 |

800*700*950 |

|

TDYZ-800 |

800 |

200 |

21 |

1.5 |

0.1-0.2 |

XWD4-71-1.5 |

900*1000*1100 |

|

TDYZ-1000 |

1000 |

250 |

21 |

1.5 |

0.2-0.3 |

XWD4-71-1.5 |

1200*950*1300 |

|

TDYZ-1200 |

1200 |

250 |

21 |

1.5 |

0.3-0.5 |

XWD4-71-1.5 |

1200*1470*1700 |

|

TDYZ-1500 |

1500 |

300 |

21 |

3 |

0.5-0.8 |

XWD5-71-3 |

1760*1500*1950 |

|

TDYZ-1800 |

1800 |

300 |

21 |

3 |

0.8-1.2 |

XWD5-71-3 |

2060*1700*2130 |

|

TDYZ-2000 |

2000 |

350 |

21 |

4 |

1.2-1.5 |

XWD5-71-4 |

2260*1650*2250 |

|

TDYZ-2500 |

2500 |

450 |

14 |

7.5 |

1.5-2.0 |

ZQ350 |

2900*2000*2750 |

|

TDYZ-2800 |

2800 |

450 |

14 |

11 |

2-3 |

ZQ350 |

3200*2200*3000 |

|

TDYZ-3000 |

3000 |

450 |

14 |

11 |

2-4 |

ZQ350 |

3400*2400*3100 |

|

TDYZ-3600 |

3600 |

450 |

13 |

18.5 |

4-6 |

ZQ400 |

4100*2900*3800 |

Organic Fertilizer Pan Granulator Machine

- The yield rate can reach more than 93%.

- The reducer and motor are driven by flexible belts, which can start smoothly, reduce the impact force, and improve the service life of the equipment.

- The bottom of the granulator plate is reinforced by a number of radiating steel plates, which is sturdy and durable, never deformed, thickened, heavy, and solid base design, no need for anchor bolts, and stable operation.

- The service life is doubled. The granulation surface plate is lined with high-strength glass fiber reinforced plastic, which is anti-corrosion and durable.

- The machine has the advantages of uniform granulation, high ball forming rate, stable operation, strong and durable equipment, and long service life.

The raw material powder is evenly stirred by pre-adding water, and input into the dish. As the dish rotates, the material gradually forms into a ball in the body of the dish by rolling, and reaches the predetermined diameter before being out of the dish, and then transported to the next process.

The disc revolves at a certain angle with the horizontal plane. Add basic fertilizer powder mixed according to the formula into disc in the process of revolving. The powder will rise along with the revolving disc under the friction between the powder and the disc, on the other hand, the powder will fall down under the function of its gravity. At the same time, the powder is swun towards the disc edge out of the centrifugal force. With the spraying of cementing agent water, the powder material rolls in a certain trace under the function of these three forces. It gradually shapes in the required size, then overflows by the disc edge.